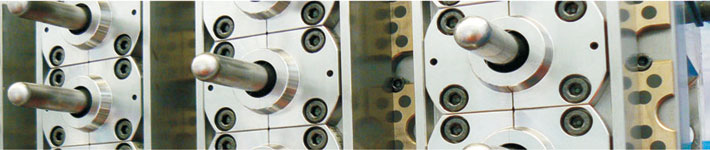

Preform Mould

SINOPK is a famous preform mould maker in China, which is established on 2004 year based on Sino Mould. It is an innovating company for various preform mould design, preform mould components machining process, preform molds standard components mass production and preform mould manufacturing etc. All these actions are aimed on high speed injection and prolong preform mould running life.

From 2006 year's turnover USD 1.5M till 2009 year's USD 5.6M, Sino Package Mould has become one of the biggest PET preform mould and cap, closure mold manufacturers in China. During the past 4 years developing, SINO-PK has proved that the focusing on bottle mold and cap mold can bring the great achievements on quality and company's developments.

Based on Sino Mould’s technologies and mentalities of mould manufacturing, by 4 years researching and developing on various complex cap mold, SINO-PK has successfully realized the mold manufacturing technologies’ breakthrough. In 2008 year, SINO-PK has succeeded in 96 cavities 37g PET preform mould manufacturing and mass production testing, also in the same year, SINO-PK has made several sets of 64 & 72 cavities ECO cap mold with cycle time 12 to 15 seconds high speed injection. In 2009 year, SINO-PK has successfully made 64 cavities toothpaste top flip cap mold with the unscrewing cores, automatic top flip closing and special ejection system. This toothpaste cap was delivered to Peru, from this mold; SINO-PK has got more than 6 sets of toothpaste mold orders in 2009 year.

SINO-PK trusted that the innovation of the mould can keep company improving and developing. To make a good quality preform molds or cap mould, we need to make excellent preparations.

A. SINOPK has very luxuriant mold design experiences.

· We need a strong preform mould and cap mold design team..

· The design team should have very good mould design and manufacturing mentalities.

· The mould design team should keep the company’s experience and technologies inheritance, in the same time, the team should keep on researching and developing for preform molding and cap molding.

B. SINOPK has strong machining capacity, machining capacity is referring:

· SINO-PK invested more than 7M USD for the tooling machines from Europe and Japan.

· We have the most scientific machining process and luxuriant tooling process experience.

· We have rigorous dimension controlling system.

C. SINO-PK teams training. SINO-PK has more than 400 hours training for company culture, preform cap mould technologies, company standard and policies studying… all these training have kept the team fresh ideas, made all the teams know the importance to follow up company’s standards.

D. SINO-PK has the standard and policies as follows:

· Preform mould design standard

· preform mould standard assembling process

· cap mold standard assembling process also

· Cap mold design standard

· CNC milling processing standard

· Lathing machining processing standard

· Cylindrical grinding processing standard

· Various machining quality standard

· SINO-PK general tolerance & special tolerance standard

· SINO-PK preform mould and cap mold hot runner system standard

· SINO-PK preform mould and cap mold components standard

· SINO-PK moulds testing standard requirements

SINO-PK do everything is for preparation of 3 or 5 years later, based on the rigorous quality mentalities on manufacturing, SINO-PK is now studying on medical moldings developing, hopeful that on 2010 year, SINO-PK will be the top quality medical molds suppliers in the world.

Welcome to your contacting to SINO-PK for preform molds and cap mold custom. Your consulting for PET preform molding and plastic cap molding solutions are also welcomed.