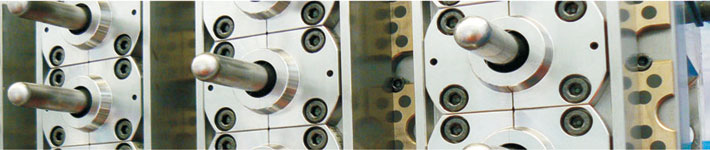

Cap mould

- Total 0Page0Records

SINO PACKAGE MOULD CO. is supplying various cap mould for mineral water, gas water and juice cap mould, 48 cavities, 64 cavities and 96 cavities cap mold. Cap mould basic tooling spec. is listed out as follows:

- cap mould cavity steel:

Stavax S420 made in Sweden, stainless, heat treatment with HRC50±2

- cap mould core steel:

DIN 1. 2083 made by Thyssen Krup German, stainless heat treatment with HRC48±2.

- cap mould stripper and slides steel:

DIN 1. 2316 made by Thyssen Krup German, stainless heat treament with HRC55±2.

- cap mould A/B/C plate steel:

718 steel made by Shanghai Bao steel, prehardened with HRC35±2, Nickel plating is available.

- cap mould other plate steel:

P20 steel made by Shanghai Bao steel, prehardened with HRC30±2. Nickel plating is available.

- cap mould guiding system steel:

SKD 61 made in Japan with HRC61±2.

- cap mould durable parts material:

Durable copper with lubrication graphite inserted.

- cap mould components spare quantity:

Core, cavity, stripper inserts, hot runner nozzle's standard spare is 12.5 to 25% based on the cavities nr. of the closure mould.

- cap mould production safety devices:

Stroke switches and electric eyes.

- cap mould ejection way:

by the machine knock out.

- cap mould cooling water:

cap mould cooling water need 8 to 15 centigrade degree soft water.

- cap mould cavities C-C distance:

As min. as possible for cap mould X and Y C-C distance.

- Molded cap weight tolerance:

0.1% to 0.25% based on the cap size and shape.

- cap mould hot runner system:

Anole hot runner system professionally design for small volume injection hot nozzle, with the temperature controlling system. Heating elements and thermocouples are made in German.

- cap mould water connectors:

Nozzle connectors with the water channel on the plate diameter 16mm, water nipple measured up with D.M.E 3/4 B.S.P standard, connected with one stainless water manifold.

- cap mould cavities Nr.:

SINO-PK cap mould cavities Nr. from 2 cavities to 72 cavities.

- cap mould cycle time:

Cap mould (standard cap closure mould) cycle time from 5 to 20 seconds if the cavities Nr. from 2 to 72 cavities.

- cap mould stocked standard components:

- -hot runner nozzle

- -heating elements

- -durable pcs

- -water nipples

- -water manifolds

- -ejector connectors

- -o-ring

- -copper water pipe of the cores

- -thermocouples

- -valve pins

- -wire plugs

- ......