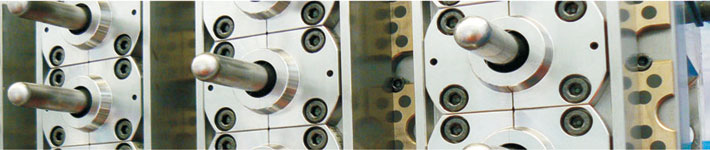

Preform moulds tooling

Preform moulds tooling equipments and the preform moulds components tooling process determine the preform moulds quality. If the mould design is done well while the components dimensions are not precise, it will not result in good quality molds. Hence, it is very important that all the steps are carried out correctly, careful and in the most precise manner.

There are several equipments that are used for perform mold tooling. These are mentioned as below:

- Rough lathe machines

- Digital lathe machines

- High speed lathe machines

- Plane surface grinding machines

- Cylindrical grinding machines

- CNC tooling center

- Boring machines

- EDM machines

- Gun grill machines

- Taping machines

The tooling process is a tedious process. Different tooling process choices cause different tooling results. For example, for the preform moulds core tooling, we can choose both high speed lathe machining as well as cylindrical grinding machine tooling. But the two different machines give different results. The cylindrical grinding machine is used to work out the conic area of the preform moulds cores with very accurate dimensions. High speed lathe machine can also be used for this purpose. But the surface finishing that result with the use of lathe is not as good as the one done by the grinding one. This is a perfect example for preform moulds tooling process machines selections.

A quality check point is maintained after each operation to ensure that it is done right.