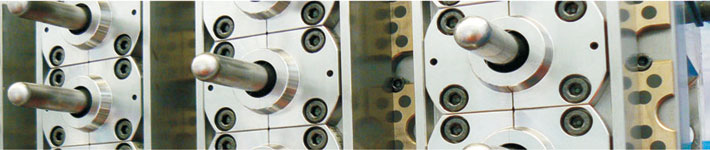

Preform molding R&D

Preform molding researching

Constant technological improvement, technological innovation on preform molding makes SINOPK the industry leader in PET Preform Mold and cap closure mold manufacturing. By offering the top quality solutions of PET Preform molding and various plastic cap molding to the market, SINOPK has won high praise from the market. It is because we know how, and we do what should be done.

- Preform molding researching for reducing the cycle time.

In order to reduce the PET preform molding cycle time, SINOPK optimized the cooling system of the preform mold and in the same time, we designed one special vice cavities which can make the preform cooling in outside of the mould. This can reduce the preform molding cycle time by 10 seconds.

- Preform mold cavities distance reduction.

In order to use smaller tonnage of the preform molding machine to approach biggest economical production, SINOPK made the cavities distance as small as possible, this is not only reduced the preform molding machine size, also reduce the PET material heating and melting time to improve the preform molding quality, this improved the bottle blowing quality.

- Preform mold maintenance

When preform molding process, sometime, if there is any cavities, cores or preform mold other components was damaged. In the old design, the preform molding has to be stopped and we have to release the preform mold from the molding machine to disassemble it for components changing. This will cost a lot of time and also very complex and dangerous. SINOPK has solved most of the components can be changed on the molding machine, in this way, we avoid preform molding production time losing and keep the maintenance become very convenient.

- Detector for the complete ejection during the preform molding

Due to sometime, the preform dropping is not completely, some of the molded preform will be stopped on the cores when it drop down, when this time the mold clamping must damage the preform mold completely. In order to stop the preform mold clamping if there is any preform stick on the mold, we use the electric eye to control the preform molding machine clamping.

- Preform Mold / Cap Mould multi-cavities mould design improvements.

SINOPK has more than 25 preform Mold / Cap Mould designers, we had the technical meeting by each week in the past 5 years, in the technical meeting, and we improved to our ready made mould structure and develop higher cavities nr. Preform Mold / Cap Mould, from 32 to 64, to 72…up to now, we have successfully offered 128 cavities Preform Mold / Cap Mould and will continues to develop 160 cavities in 2012 year.

- Preform Mold valve gate injection system R&D.

The hot runner system of Preform Mold / Cap Mould is one of the key points, SINOPK has a very special PET molding valve gate system which can avoid material leakage...it is one of the best PET hot runner system in world.

- Cap Mold injection system R&D.

SINOPK has a very special hot runner design which is suitable for small volume PP, PE material injection molding. This hot runner system reduces the injection pressure, keep the injection distance and the injection pressure and filling volume to be equaled.