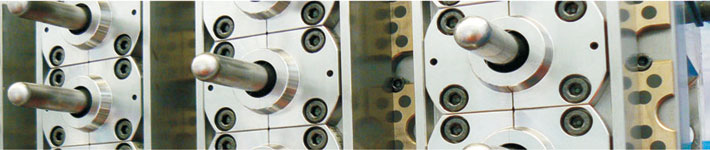

Plastic water closure moulds

Plastic water closure moulds mainly have two structures, one is with slider, and another is without slider. The mould with slider, no need second treatment, and for mould without slider need ring cutting machine to cut the cap after production.

Generally, water bottle with neck size 28mm, so the closure always with 28mm, to reach high output quantity, it no needs unscrewing, usually with force ejector system. The cycle time of closure mould without slider can reach around 6-8s, the mould with slider, the cycle time is around 10-12s.

Due to the high output, water closure moulds always with multi cavities, like 24cav, 32cav, 48cav, 64 cav… in this way, the mould can reach a very high output, the closure have small profit, so the output is very important.

If you want to make high output closure production line, pls don’t hesitate to contact me.

Posted by Elaine

E-mail: service@sinogroupe.com